Using the standard fixture kit provided by CHD to make standard test fixtures and customized test systems, you can achieve high-quality testing in a short period of time. The test fixtures are perfectly matched with our test system units.

To ensure the high quality and perfect function of PCBs, electronic components, and finished products, these products need to be tested with the latest testing equipment for specific functional requirements. This can be done during the production process or after the production assembly.The end-of-line test system (EOL) can reliably test the function of finished products and components. There is no problem with the combination of PCBA functional testing (FCT) and online circuit testing (ICT). During ICT testing, the lines and independent components of the PCBA are contacted through test points and checked to see if there are any defects in the lines and various components of the PCBA board.

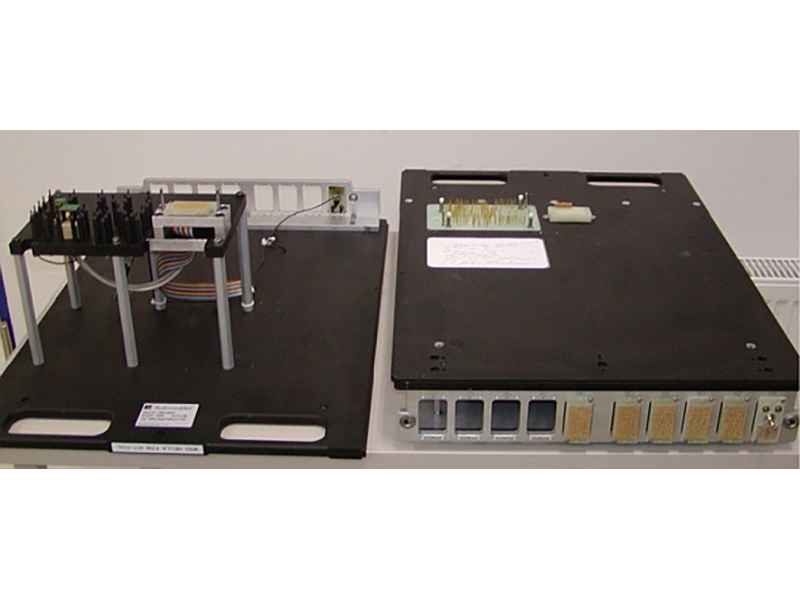

The CHD Inline handling fixture is made using CHD's standard inline kit/pylon interface. It is used in conjunction with the CHD inline handler for automatic testing at rail transfer test stations.

Suitable for inline concept FCT/Flashing/ICT.

Features:

Supports single board or panelized PCBA

Maximum supported PCB size: 400mm x 350mm

Minimum supported PCB size: 10mm x 10mm

Interface: standard CHD Pylon interface/blocks

Supports single-sided or double-sided PCBA testing

The upper Pylon can be expanded to double-layer.

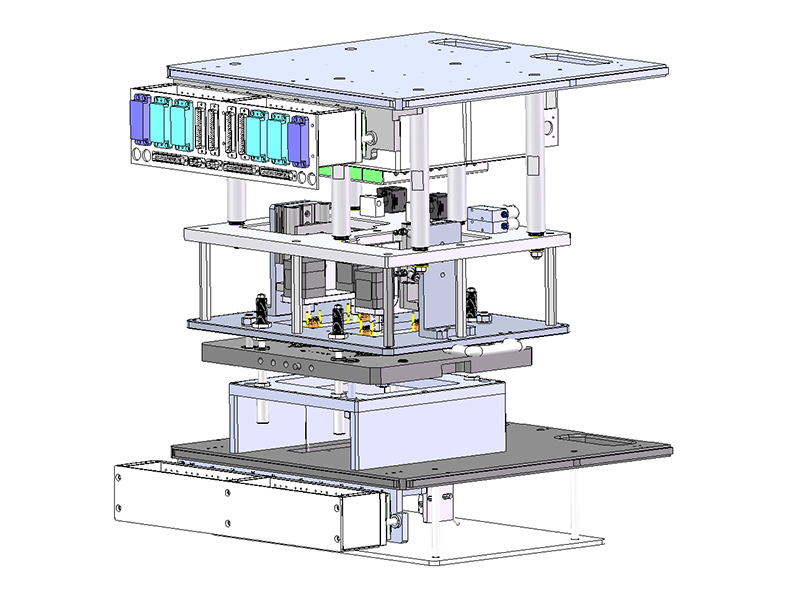

The CIPOS ICT fixture is made using a customized standard CIPOS kit. It is used for automatic testing at rail transfer test stations or multi-position test turntables.

Suitable for FCT/Flashing/ICT turntable concept

Features:

Supports single board or panelized PCBA

Maximum supported PCB size: 400mm x 350mm

Minimum supported PCB size: 10mm x 10mm

Interface: standard CHD Pylon interface/blocks

Supports single-sided or double-sided PCBA testing

The upper Pylon can be expanded to double-layer.

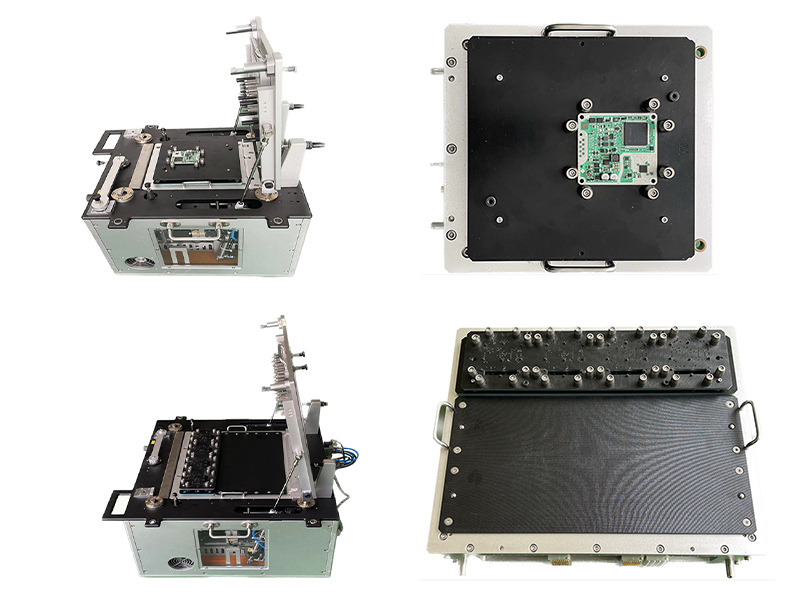

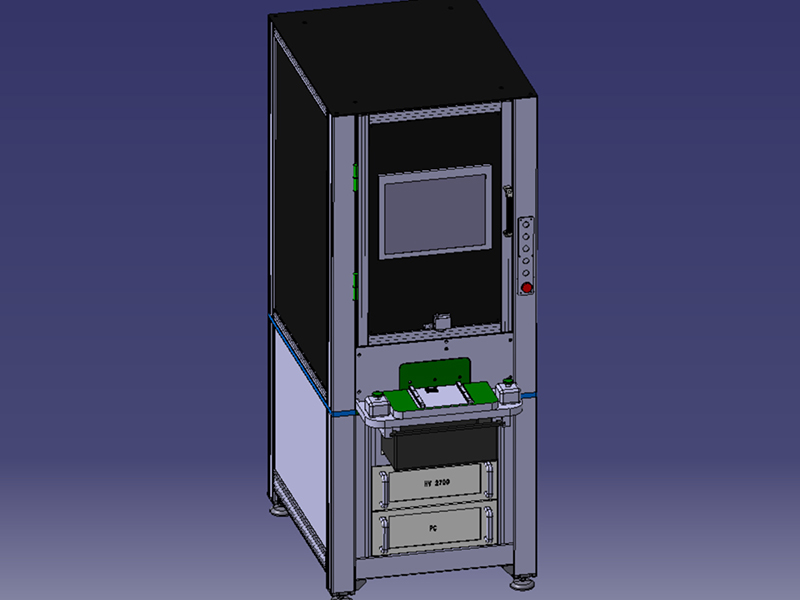

The CHD Robot Handling fixture is used in conjunction with various robots to achieve test automation. It is suitable for FCT/Flashing/ICT.

Features:

Maximum supported PCB size:

Small kit: 430mm x 466mm x 475mm (open cover height: 710mm)

Large kit: 630mm x 566mm x 475mm (open cover height: 810mm)

Construction method: Base fixture + inlay designed for multiple product models.

Quick model change by replacing the inlay model.

Built-in standard interface modules from CHD, flexible modular configuration.

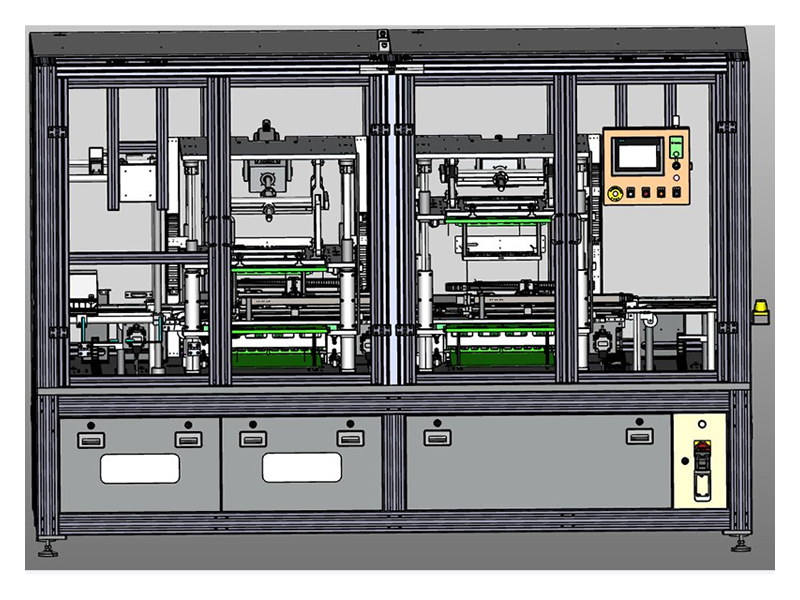

The CHD inline handler is suitable for FCT/Flashing/ICT PCBA automated test lines.

The inline handler test unit for production line operation can be flexibly used for circuit testing as well as functional and terminal testing of PCBs, electronic components, and equipment. The test points of PCBA can be on one side, both sides, or in step with multi-panel. All components can be matched with each other to achieve the best match and can be integrated into custom test and assembly lines.

CHD's test unit has a servo-driven (toggle lever press) Y-drive structure that provides very stable downforce pressure, with a maximum pressure of 5000N. It is also equipped with a fast pushrod (optional). It can achieve a processing time of less than 6 seconds for fast PCBA transmission in each step, providing up to 3,000 test paths.

Features:

Feeding system transmits PCBA at a rate of 3S/PCS.

Maximum supported PCBA size: 400 x 350 mm.

Automatic rail width adjustment: 80-350MM.

Supported weight of PCBA: 3KG.

Handler supports Servo-driver spindle press mechanism with a speed range of 0.1mm/S to 200mm/s.

Downforce up to 6200N (maximum 2048 3N needles).

Height accuracy of the downforce system: ±0.02MM.

1 stage/2stage standard Pylon interface.

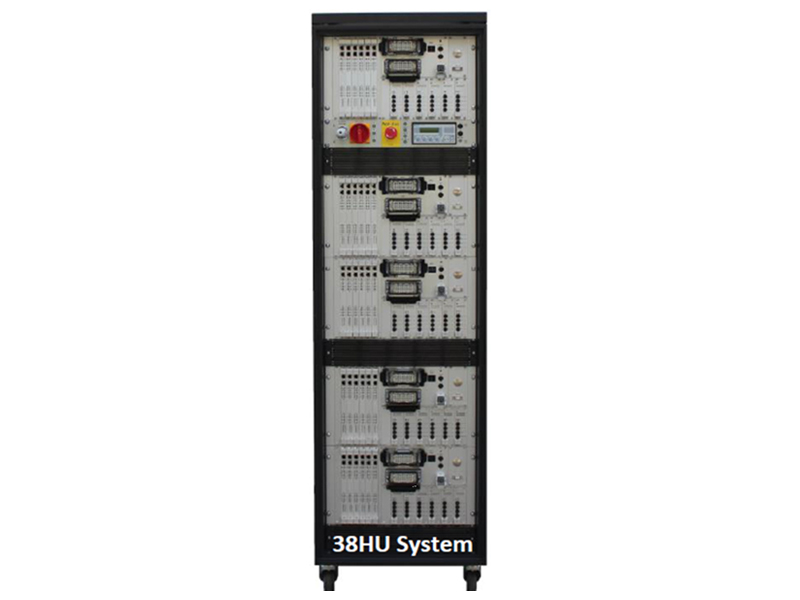

1> Aeroflex ICT Fixture and programming

Special Aeroflex 4220/4250 fixture kit, and customized test programs are available.

2> Teradyne ICT Fixture and programming

Special Teradyne LH series fixture kit, and customized test programs are available.

Customized fixtures and test programs can be provided based on CHD's standard kit according to customer needs.

Customized fixtures and test programs can be provided based on CHD's standard kit according to customer needs.

Customized fixtures and test programs can be provided based on CHD's standard kit according to customer needs.

Support:INFOO|Record number:沪ICP备2022012804号-1