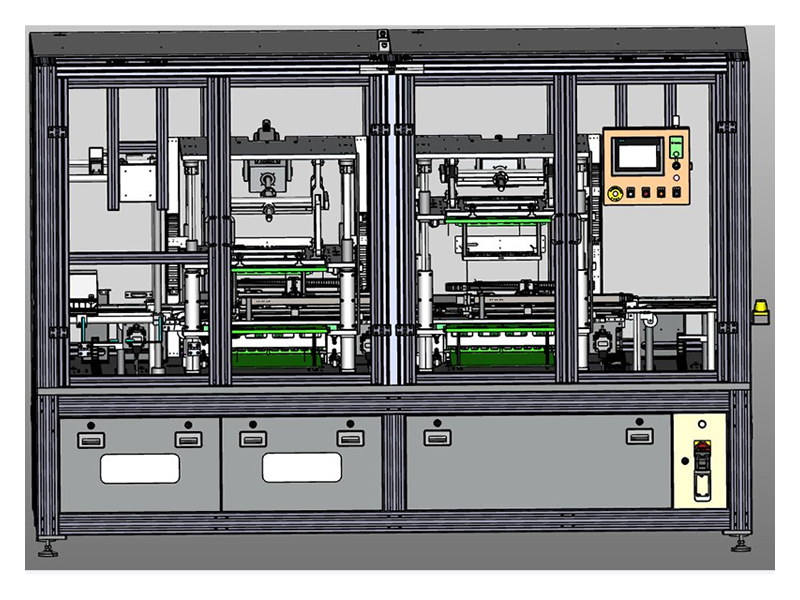

The CHD inline handler is suitable for FCT/Flashing/ICT PCBA automated test lines.

The inline handler test unit for production line operation can be flexibly used for circuit testing as well as functional and terminal testing of PCBs, electronic components, and equipment. The test points of PCBA can be on one side, both sides, or in step with multi-panel. All components can be matched with each other to achieve the best match and can be integrated into custom test and assembly lines.

CHD's test unit has a servo-driven (toggle lever press) Y-drive structure that provides very stable downforce pressure, with a maximum pressure of 5000N. It is also equipped with a fast pushrod (optional). It can achieve a processing time of less than 6 seconds for fast PCBA transmission in each step, providing up to 3,000 test paths.

Features:

Feeding system transmits PCBA at a rate of 3S/PCS.

Maximum supported PCBA size: 400 x 350 mm.

Automatic rail width adjustment: 80-350MM.

Supported weight of PCBA: 3KG.

Handler supports Servo-driver spindle press mechanism with a speed range of 0.1mm/S to 200mm/s.

Downforce up to 6200N (maximum 2048 3N needles).

Height accuracy of the downforce system: ±0.02MM.

1 stage/2stage standard Pylon interface.